Lawrence Livermore National Laboratory (LLNL) scientists have combined biology and 3D printing to create the first reactor that can continuously produce methanol from methane at room temperature and pressure.

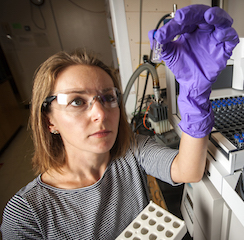

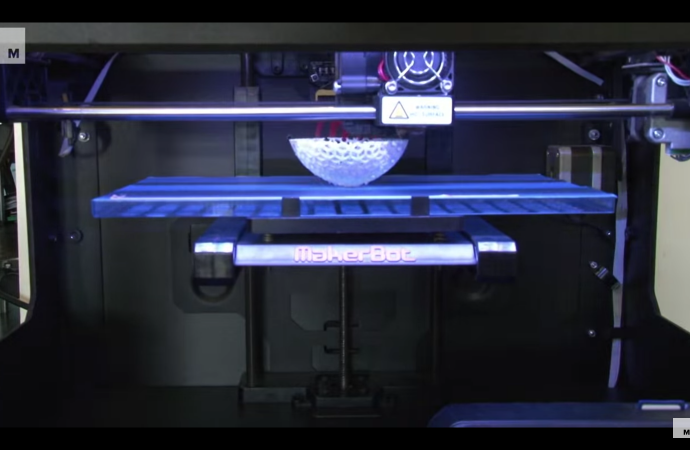

The team removed enzymes from methanotrophs, bacteria that eat methane, and mixed them with polymers that they printed or molded into innovative reactors.

3D-Printed_Polymer_copy

Advances in oil and gas extraction techniques have made available vast new stores of natural gas, which is composed primarily of methane. However, a large volume of this methane is leaked, vented or flared, partly because the gas is difficult to store and transport compared to more-valuable liquid fuels.

Methane emissions also contribute about one-third of current net global warming potential, primarily from these and other distributed sources such as agriculture and landfills.

Current industrial technologies to convert methane to more valuable products, like steam reformation, operate at high temperature and pressure, require a large number of unit operations and yield a range of products.

As a result, these techniques have a low efficiency of methane conversion to final products and can operate economically only at very large scales.

A technology to efficiently convert methane to other hydrocarbons is needed as a profitable way to convert “stranded” sources of methane and natural gas (sources that are small, temporary or not close to a pipeline) to liquids for further processing.

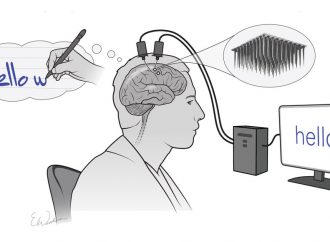

The only known catalyst (industrial or biological) to convert methane to methanol under ambient conditions with high efficiency is the enzyme methane monooxygenase. The reaction can be carried out by methanotrophs that contain the enzyme, but this approach inevitably requires energy for upkeep and metabolism of the organisms.

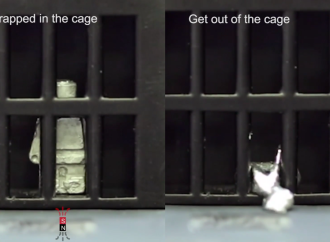

Instead, the LLNL team separated the enzymes from the organism and used them directly. In so doing, the team found that isolated enzymes offer the promise of highly controlled reactions at ambient conditions with higher conversion efficiency and greater flexibility.

The team further found that the 3D-printed polymer could be reused over many cycles and utilized in higher concentrations than are possible via the conventional approach of the enzyme dispersed in solution.

Source of Image: 3D Printing.com

To contact the author of this article, email engineering360editors@ihs.com

Leave a Comment

You must be logged in to post a comment.