Scientists are trying to convert carbon dioxide emissions into something of value—without using too much energy

We humans emitted 35.9 metric gigatons of carbon dioxide into the atmosphere in 2014, mostly from burning coal and natural gas in power plants, making fertilizer and cement, and other industrial processes. If chemists could capture carbon dioxide and turn it into chemical building blocks for other products, the way plants do, says Cornell University chemical engineer Lynden Archer, “carbon dioxide would not be a nuisance anymore, but a gift.”

For years scientists have been trying to store carbon dioxide captured from exhaust flues at power plants and other emitters, mostly by injecting it deep underground. Without large subsidies, however, this expensive carbon sequestration process may not be economically viable. Injecting carbon dioxide into old oil wells to drive out more oil is one application, but it’s not enough, and it’s not clear it even pays, given current low oil prices. Proponents of utilizing carbon rather than storing it hope they will profit by creating something of value from this waste product. The most likely applications use the gas as a raw material for making chemical products, which could also pay off by replacing petrochemicals with something greener.

These proponents face a difficult chemistry problem. Carbon dioxide is a stable molecule, and doesn’t store much energy in its chemical bonds. To use it, chemists have to add energy, often through heating, which usually requires electricity. Much of that comes from power plants that burn coal or natural gas—emitting more carbon dioxide into the atmosphere, even more than was captured.

Engineers, chemists and other researchers say new technologies are changing the picture. Paul Bunje, senior scientist in the Energy and Environment group at the XPrize Foundation, hopes that awarding a big prize for a solution will stimulate a diverse group of technologists. Next Wednesday, the foundation will announce that more than 40 teams are competing to win a $20 million prize. The winner of the Carbon XPrize, to be announced in spring 2020, will sequester the most carbon dioxide into a product of greatest net value. Some teams aim to make polymers, or fuels to replace gasoline, or industrial chemicals.

In the longer term, all the different companies producing one chemical or another could make up a carbon-utilization industry that could make a difference. A problem on the scale of climate change needs multiple solutions, Bunje says.

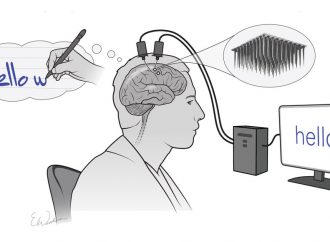

“The question now is how can people in chemistry create new reactions, new mechanisms to use carbon dioxide as a feedstock?” says Cornell’s Archer, who is also a Carbon XPrize advisory board member. This week in Science Advances, he offers one answer: a fuel cell that generates electricity while converting carbon dioxide into a commodity chemical. Archer and his student Wadji Al Sadat built a prototype reactor that combines carbon dioxide with aluminum and oxygen to produce oxalates. Oxalates are used to make acids, rust removers, fabric dyes and other industrial chemicals.

Archer is well aware of the pitfalls of trying to do environmentally friendly chemistry with carbon dioxide. “Usually you consume so much energy that it’s cost prohibitive—but we get energy back,” he says. “That surprised us.”

The cell runs on aluminum and air. Inside, oxygen reacts with an electrode made of aluminum to form a highly reactive aluminum superoxide capable of reacting with otherwise reluctant carbon dioxide. The two react to generate aluminum oxalate. The fuel cell captures some energy from these chemical reactions, and although it requires a voltage to drive the reaction, the process appears to generate more electricity than it consumes, Archer says. Because the metal is consumed, choosing the right one is key. He settled on aluminum because it’s abundant and inexpensive. And even though aluminum production emits carbon dioxide, Archer hopes his system will capture enough carbon within oxalates to offset that.

The Cornell group cautions that it doesn’t fully understand the chemical reactions involved. The early version of the fuel cell uses an expensive material called an ionic liquid as the electrolyte, for example. If it plays a critical role and can’t be replaced, the technology may not be viable, says Archer.

Oxalates are a niche product, as are many of the chemicals being made by startups working on carbon utilization. But some are aiming big. Skyonic’s pilot plant in San Antonio, Texas, captures emissions from a cement plant and turns them into limestone and acid. Solidia Technologies sequesters carbon dioxide in concrete itself. And other companies in various stages are working on making plastics, alternative fuels and chemical feedstocks.

Without pointing fingers at any project in particular, Howard Herzog says many of those that promise to use captured carbon look a little too good to be true. Herzog is a senior research engineer at the MIT Energy Initiative and a proponent of carbon sequestration. “Carbon dioxide is spent energy,” he says. Getting value out of carbon dioxide in the form of commodity chemicals or energy, without putting more energy in somewhere in the life cycle of the product, is extremely difficult. “You can’t win in terms of energy. Thermodynamics tells us that,” Herzog says.

Although Herzog admits that some of the companies may be profitable, he’s skeptical about the potential for carbon utilization to have a significant environmental impact. He was a lead author of the 2005 IPCC Special Report on Carbon Dioxide Capture and Storage, and says the report’s conclusions about carbon utilization still hold: The potential to make a dent in global emissions is small. Even if the chemical industry used carbon dioxide to make all its products—something no one thinks is likely—they couldn’t sop up all the emissions.

Kendra Kuhl, co-founder of Opus 12, a startup in Berkeley, Calif., is well aware that carbon utilization won’t fully solve the world’s emissions problem. Opus 12 is developing an electrochemical reactor that uses novel catalysts and renewable electricity to turn carbon dioxide into polymer building blocks and other chemicals. Kuhl says Opus 12 will compete for the Carbon XPrize. And even though there is not enough demand for products to consume a large share of carbon dioxide emissions, she says that given the environmental consequences of continuing to dig up fossil fuels to feed the petrochemical industry, it’s worth trying to use carbon dioxide instead. “We need a new way of doing chemistry.”

Source: Scientific America

Leave a Comment

You must be logged in to post a comment.