3D printing with bio ink has gotten better, now they are able to 3D print human cartilage available to replace damaged ears, noses, and knees.

Researchers from the Wallenberg Wood Science Center in Sweden have discovered a way to print cartilage for knees, noses and ears with a new 3-D bio-printing ink that contains human cells. The method has been tested on an in vivo mouse model and could open the door to new accurately printed implants.

“Three-dimensional bio-printing is a disruptive technology and is expected to revolutionize tissue engineering and regenerative medicine,” said Paul Gatenholm, Ph.D, who worked on the project. “Our team’s interest is in working with plastic surgeons to create cartilage to repair damage from injuries or cancer. We work with the ear and the nose, which are parts of the body that surgeons today have a hard time repairing. But hopefully, they’ll one day be able to fix them with a 3-D printer and a bio-ink made out of a patient’s own cells.”

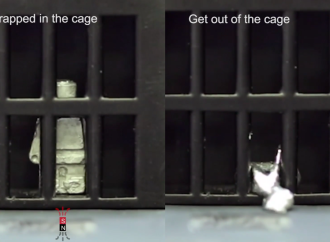

To make this possible, the team first needed to develop the ink that contained human cells and would be able to maintain its shape after printing, because previous materials used collapsed. To do so, Gatenholm’s team mixed polysaccharides, from brown algae and tiny cellulose fibrils, either from wood or made by bacteria, with human chondrocytes, which are cells that build up cartilage. With the mixture, the researchers were able to print living cells in a specific shape, such as that of an ear, and they maintained their form even after printing. The printed cells were also able to produce cartilage in a laboratory dish.

“But under in-vitro conditions, we have to change the nutrient-filled liquid that the material sits in every other day and add growth factors,” said Gatenholm. “It’s a very artificial environment.”

From that point, in order to conduct some tests, the team printed tissue samples and implanted them in mice. The cells survived and produced cartilage, so the researchers took it to the next level and boosted the number of cells by mixing the chondrocytes with human mesenchymal stem cells from bone marrow.

Before they can begin testing on humans, more work needs to be done to ensure the most direct route.

In addition to cartilage printing, Gatenholm’s team is working with a cosmetic company to develop 3-D-bio-printed human skin. Because European cosmetic companies are now prohibited from testing on animals, they hope to use printed skin to test out makeup and anti-wrinkling techniques.

Source: Electronics 360

Leave a Comment

You must be logged in to post a comment.