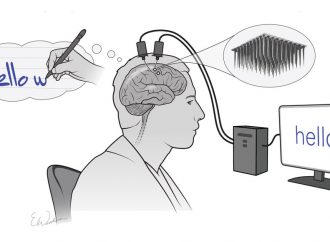

Two interns are prototyping soft robots made using 3D printing and silicon.

Source: Interesting Engineering

We often think of robots as looking humanism, being hard and made of metal. But the next generation of robots is more likely to be soft squidgy and agile.

Called ‘soft robots’ these critters are being developed to do everything from explore disaster zones to performing surgery. Now soft robots are being developed to help us explore space.

Two interns at NASA are developing soft robotic actuators that could be used on the next moon mission. Interns Chuck Sullivan and Jack Fitzpatrick working at NASA’s Langley Research Center in Hampton, Virginia.

“When you actuate the soft robot, it changes how you use the material properties,” Fitzpatrick said in a statement.

“A piece of rubber going from flat to the shape of a finger, it changes the material into something else.”

Soft, flexible and adaptable

Soft robots have many advantages, they are flexible, have the ability to adapt to new environments and in some cases can be repaired and replaced cheaply and quickly.

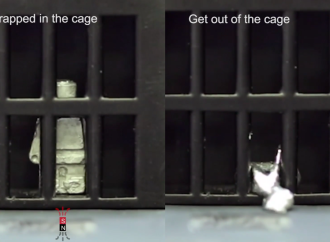

Similar to living organisms some soft robots can dramatically expand their range of motion to squeeze through tight openings or under obstacles.

Sullivan and Fitzpatrick are still at the testing phase of their design but have so far seen good results. The interns are building the soft actuators by 3D-printing a mold and then pouring it into silicone or another type of flexible substance.

“By design, the actuator has chambers, or air bladders, that expand and compress based on the amount of air in them,” NASA said in the statement.

A new generation of inflatables

“Currently, these two interns are operating the design through a series of tubes in the air bladders, allowing them to control the movement of the robot. By adjusting the amount of air in the chamber of the soft robotic actuator, the robot can flex and relax, just like a human muscle.”

There are four crucial properties to the robots: mobility, joining, leveling and shaping. Mobility is how the robot actually moves through its environment, joining refers to have the robots can link together (for example, to make a large temporary shelter).

Leveling is the way the actuators can create a surface, such as filling in space underneath a lunar habitat, and shaping looks at how to add strength to existing materials.

Testing to continue throughout the summer

“We see these four things as the crux of the problem. Once we can accomplish those in individual unit tests, we would like to figure out ways to combine them, so maybe we combine mobility and joining,” Sullivan said in the same statement.

The interns will receive feedback on their work so far from robotics experts and researchers across the country.

From there they will incorporate the advice they received to continue their research and prototyping throughout the summer.

Leave a Comment

You must be logged in to post a comment.